A favorable displacement pump. For every transformation of the pump, a set volume of liquid is relocated despite the resistance against which the pump is pressing. It is self-priming, and offers almost continuous provided ability no matter the pressure. The rotary pump consists of a fixed casing having equipments, webcams, screws, plungers or comparable aspects actuated by rotation of the drive shaft. A variety of pump kinds are included in this classification, amongst which are the gear pump, the screw pump, as well as the rotating vane pump.

Rotating pumps serve for pumping oil and also various other liquids of high viscosity. In the engine area, rotating pumps are used for handling lube oil as well as fuel oil and appropriate for taking care of fluids over a vast array of viscosities. Rotary pumps are designed with extremely tiny clearances in between rotating parts and stationary parts to minimize leakage (slippage) from the discharge side back to the suction side. Rotating pumps are developed to run at relatively reduced rates to keep these clearances. The procedure at greater rates triggers disintegration and also too much wear which lead to enhanced clearances with a succeeding reduction in pumping capability. Classification of the rotating pumps is typically based on the kinds of revolving aspect.

- Gear pump - The straightforward equipment pump has 2 spur equipments that harmonize with each other as well as rotate in contrary directions. One is the driving gear, as well as the various other is the driven gear. Clearances between the equipment teeth (outdoors size of the equipment) and the case as well as in between the end face and also the housing are just a couple of thousandths of an inch. As the gears turn, they unmesh and also fluid flows right into the pockets that are abandoned by the meshing equipment teeth. This creates the suction that attracts the liquid right into the pump. The liquid is then carried along in the pockets developed by the gear teeth as well as the covering. On the discharge side, the fluid is displaced by the meshing of the gears and dislodged with the discharge side of the pump.

- Rotary vane pumps - The rotary vane pump has a cylindrically-bored housing with a suction inlet on one side and also a discharge outlet on the other side. A blades (smaller in diameter than the cylinder) is driven regarding an axis that is put above the facility line of the cylinder to give minimal clearance in between the blades and cyndrical tube at the optimal as well as leading clearance near the bottom. The blades brings vanes (which move in and out as the rotor turns) to maintain closed areas in between the blades as well as the cylinder wall. The vanes trap liquid on the suction side as well as bring it to the discharge side, where tightening of the area gets rid of fluid via the discharge line. The vanes slide on ports in the blades. Vane pumps are used for lube oil service and transfer, container removing, bilge, as well as generally, for managing lighter viscous liquids.

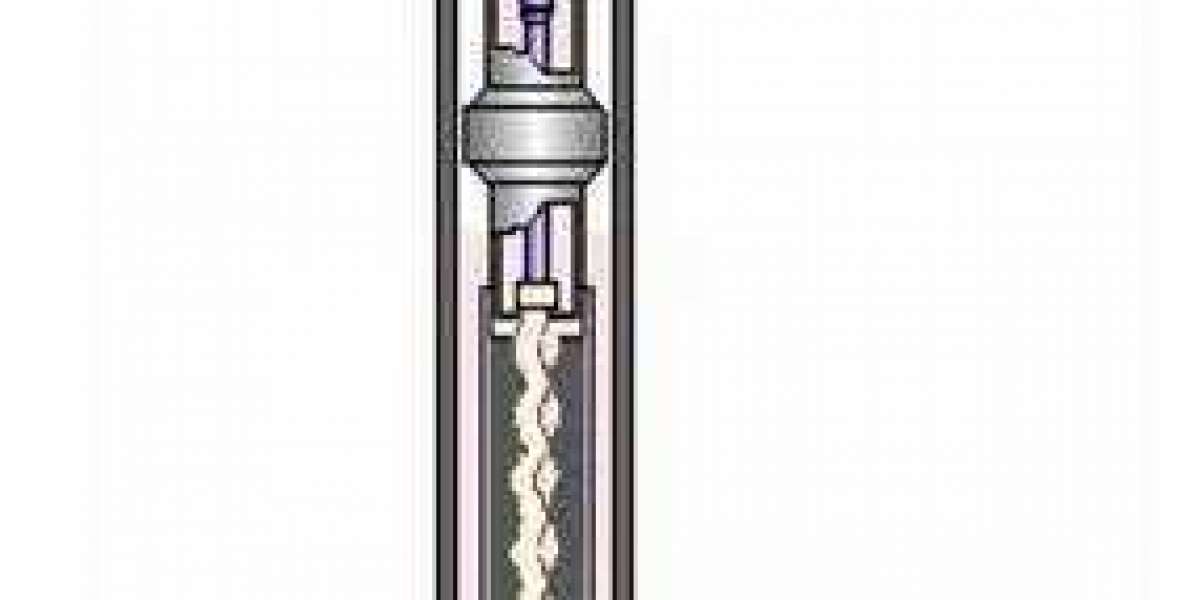

- Screw pump - There are numerous different types of screw pumps. The differences in between the different types are the variety of intermeshing screws and also the screw pitch. Screw pumps are used aboard ship to pump fuel and lube oil and to supply stress to the hydraulic system. In the double-screw pump, one rotor is driven by the drive shaft and also the other by a set of timing equipments. In the triple-screw pump, a central rotor harmonizes with two idler blades. In the screw pump, fluid is trapped and required through the pump by the activity of rotating screws. As the blades transforms, the fluid circulations in between the strings at the outer end of each pair of screws. The threads lug the liquid along within the housing to the center of the pump where it is released. The majority of screw pumps are now outfitted with mechanical seals. If the mechanical seal falls short, the stuffing box has the capacity of approving two rings of traditional packing for emergency use.

A number of pump kinds are consisted of in this classification, amongst which are the gear pump, the screw pump, and also the rotary vane pump.

- Gear pump - The easy equipment pump has two spur equipments that harmonize together and rotate in contrary directions.- Screw pump-- There are a number of different types of screw pumps. Screw pumps are used aboard ship to pump gas and lube oil and also to supply stress to the hydraulic system. In the screw pump, fluid is entraped as well as forced with the pump by the action of turning screws.