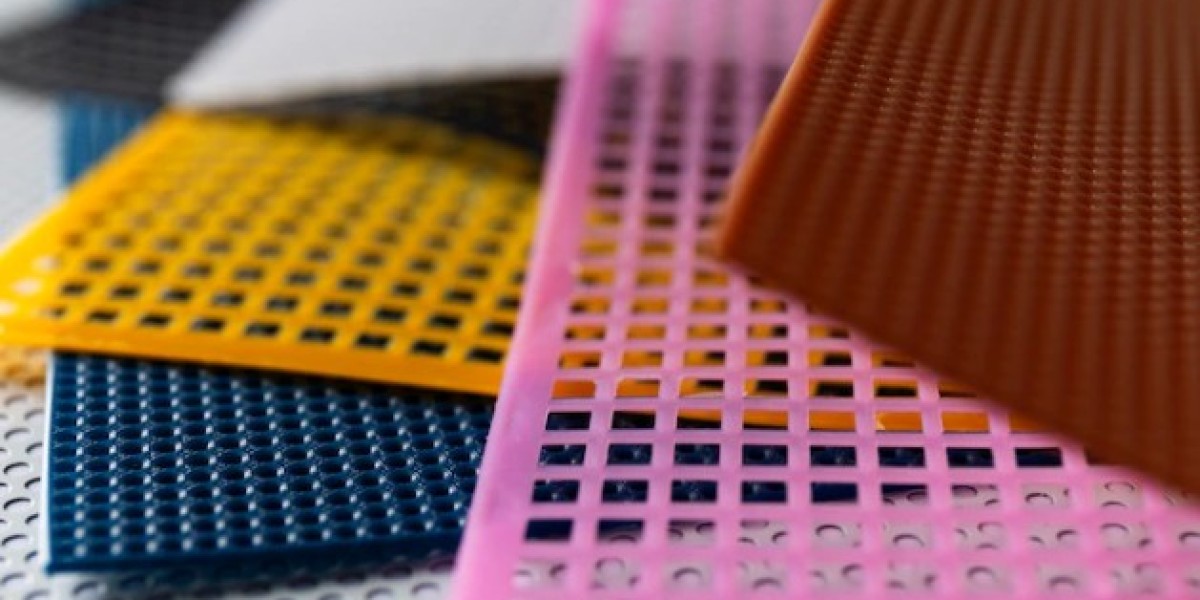

In recent years, the demand for EVA foam products has been on the rise. EVA foam, also known as ethylene-vinyl acetate foam, is a versatile material that offers a wide range of benefits and applications. In this article, we will explore the quality of EVA foam manufacturing and its various applications.

What is EVA Foam?

EVA foam is a type of closed-cell foam that is made from ethylene-vinyl acetate copolymer. It is known for its softness, flexibility, and durability. EVA foam is commonly used in various industries, including footwear, sports equipment, packaging, and automotive.

Quality of EVA Foam Manufacturing

When it comes to EVA foam manufacturing, quality is of utmost importance. High-quality EVA foam is characterized by its uniform cell structure, excellent shock absorption properties, and resistance to water, chemicals, and UV radiation. It is important for manufacturers to use high-quality raw materials and employ advanced production techniques to ensure the consistency and durability of the foam.

Applications of EVA Foam

EVA foam has a wide range of applications across different industries. Here are some of the most common applications of EVA foam:

Footwear: EVA foam is extensively used in the production of footwear, including athletic shoes, sandals, and flip-flops. It provides cushioning, support, and comfort to the wearer.

Sports Equipment: EVA foam is also used in the manufacturing of sports equipment such as yoga mats, exercise mats, and protective gear. Its shock-absorbing properties make it ideal for impact protection.

Packaging: EVA foam is widely used in packaging applications due to its excellent cushioning and shock-absorbing properties. It helps protect fragile items during transportation and storage.

Automotive: EVA foam is used in various automotive applications, including gaskets, seals, and interior components. It provides insulation, noise reduction, and vibration damping.

Crafts and DIY Projects: EVA foams sheets are popular among crafters and DIY enthusiasts. They can be easily cut, shaped, and glued to create various decorative and functional items.

Conclusion

EVA foam manufacturing plays a crucial role in providing high-quality foam products for various industries. The versatility and durability of EVA foam make it a preferred choice in applications such as footwear, sports equipment, packaging, automotive, and crafts. If you are looking for reliable EVA foam products, consider reaching out to Avetco Inc., a leading manufacturer in the industry.