In the world of manufacturing and design, precision is paramount. Whether you're crafting intricate parts for aerospace applications or creating artistic masterpieces from various materials, the ability to cut with absolute precision is a game-changer.

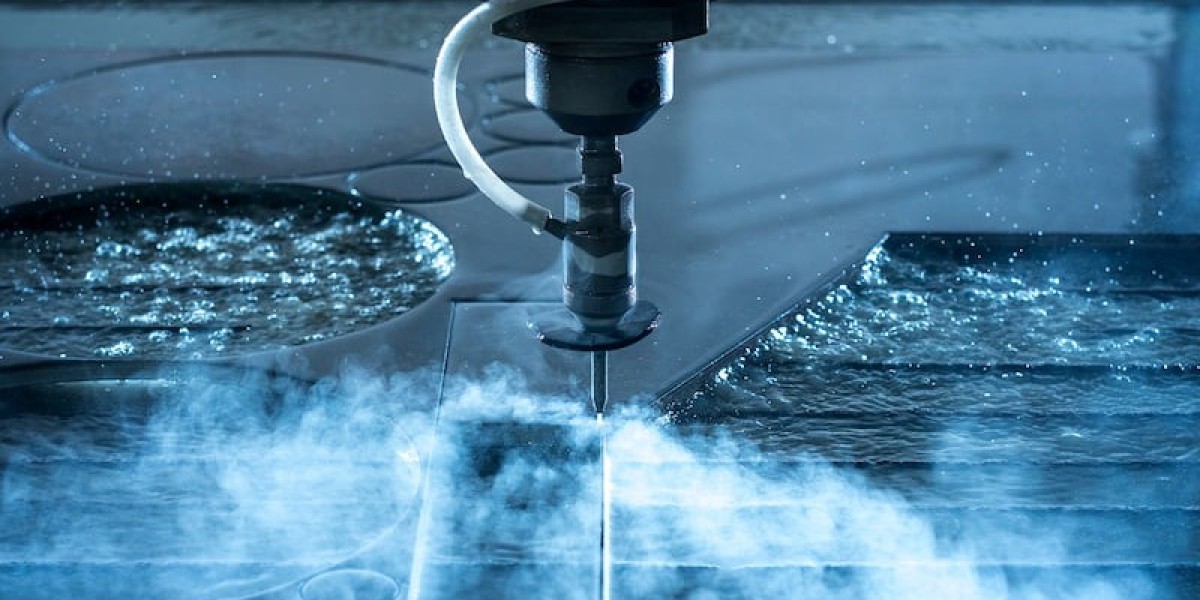

This is where waterjet services come into play, offering a versatile and highly accurate method for cutting a wide range of materials. In this article, we will explore the benefits and applications of waterjet services and how they have revolutionized the world of precision cutting and design.

Versatility and Material Compatibility

One of the standout features of waterjet cutting services is their ability to work with an extensive array of materials. From metals like steel and aluminum to composites, plastics, and even glass, waterjets can cut through them all.

This versatility is made possible by the use of a high-pressure stream of water mixed with abrasive particles, which can precisely cut through materials without generating heat. This lack of heat-affected zones ensures that the material's integrity remains intact, making waterjet cutting ideal for materials that are sensitive to temperature changes.

Environmental Friendliness

Waterjet cutting is also an environmentally friendly option compared to some traditional cutting methods. The process generates minimal waste, as the cutting stream is relatively narrow, reducing material loss. Additionally, waterjet cutting does not produce hazardous fumes or dust, making it a safer and cleaner option for both the operator and the environment.

Cost-Effective Production

While waterjet services offer superior precision and versatility, they are also cost-effective. The ability to cut a wide range of materials with a single machine means that businesses can reduce the need for multiple specialized cutting tools. This not only saves money on equipment but also reduces setup time and operational costs. Furthermore, the minimal material waste generated by waterjet cutting contributes to cost savings over time.

Applications Across Industries

Waterjet cutting services find applications across various industries. In aerospace, waterjets are used to cut complex shapes in aircraft components, ensuring optimal performance and safety. In the automotive sector, waterjet services aid in precision cutting for parts like gears and engine components. Artistic and architectural fields benefit from waterjet technology as well, allowing artists and designers to create intricate sculptures, decorative tiles, and custom metalwork with ease.

Conclusion

In conclusion, waterjet services have become the go-to choice for precision cutting and design across a multitude of industries. Their versatility, precision, environmental friendliness, and cost-effectiveness make them an attractive option for manufacturers and artisans alike.

Whether you are a manufacturer seeking to optimize production processes or an artist looking to push the boundaries of your creativity, waterjet cutting services offer the precision and flexibility you need to achieve your goals. Embracing this technology can lead to improved quality, increased efficiency, and endless design possibilities.