The setup or programming of motions and sequences for an industrial robot is typically taught by linking the robot controller to a laptop computer, desktop laptop or network. Furthermore, industrial robots can have a serial or parallel structure. Cartesian robots, additionally referred to as rectilinear, gantry robots, and x-y-z robots have three prismatic joints for the motion of the software and three rotary joints for its orientation in area. 6-axis Articulated Robots best for mechanical assembly, material dealing with, packaging, and palletizing. Engineering considerations the creation of bodily methods (e.g., an industrial robot).

Covering some essential purposes and system applied sciences that may assist perceive how industrial robots control units are architected. Our innovative analog and embedded applied sciences allow engineers to develop essentially the most intelligent and complicated robotic techniques of tomorrow. Navigate new system block diagrams and quickly discover totally examined reference designs and merchandise for your subsequent industrial, logistics or service robot design. It is an exciting time to be part of the robotic world as our globe becomes extra aware of the superb benefits of industrial robots.

World Robotics - Industrial Robots supplies global statistics on industrial robots in standardized tables and enables national comparisons to be made. It additionally presents robotic density, i.e. the variety of robots per 10,000 employees, as a measure for the degree of automation. Read extra about how industrial robots are utilized in different industries and functions.

Although companies also purchase robotic parts because of general put on and tear, this isn’t a substantial income for suppliers of end effectors, since most components are coated under long warranties. End effectors also tend to last for for much longer than the anticipated lifetime defined of their specifications. As China builds its robotic installed base, it'll see a 25 percent annual improve in demand for finish effectors from 2018 through 2023.

What makes such a system look like intelligent is the inner computational algorithms. These algorithms are the results of the application of sure computational techniques in designing and building the system. To construct an industrial robotic, for instance, requires engineers with varied kinds of data (e.g., of kinematics and dynamics) and abilities (e.g., of fabricating mechanical parts). Thus, it is reasonable to say that an engineer clearly possesses intelligence. A man-made system exhibiting to some degree this ability could also be characterized as possessing synthetic intelligence . However, low power actuators limit not solely the pressure but additionally the moving velocity of the robotic.

Earlier generations of robots needed to be separated into their very own world, whereas at present they are often built-in into the workforce. Heavily used for manufacturing within the food, pharmaceutical and digital industries, these spider-like robots are related with a typical base. The delta robot is often used for fast decide and place purposes due its precision at high speed. Sealer robots are constructed with numerous robotic arm configurations that enable the robotic to apply adhesives to any type of product. The major benefit in this utility is increased high quality, speed and consistency of the ultimate product.

They are especially desirable to switch human in hazardous, toxic, strenuous, and poor working situations. With 18 series of models, FANUC presents the widest vary of commercial robots on the planet. Covering a various vary of functions and industries, FANUC machines are simple to function and supply full flexibility. With more than 100 models, FANUC provides the widest vary of industrial robots in the world. Types of Human-Industrial Robot CollaborationThe marketplace for collaborative robots is still in its infancy. End-users and techniques integrators are nonetheless gaining experience on what works and doesn’t in the design and implementation of collaborative functions.

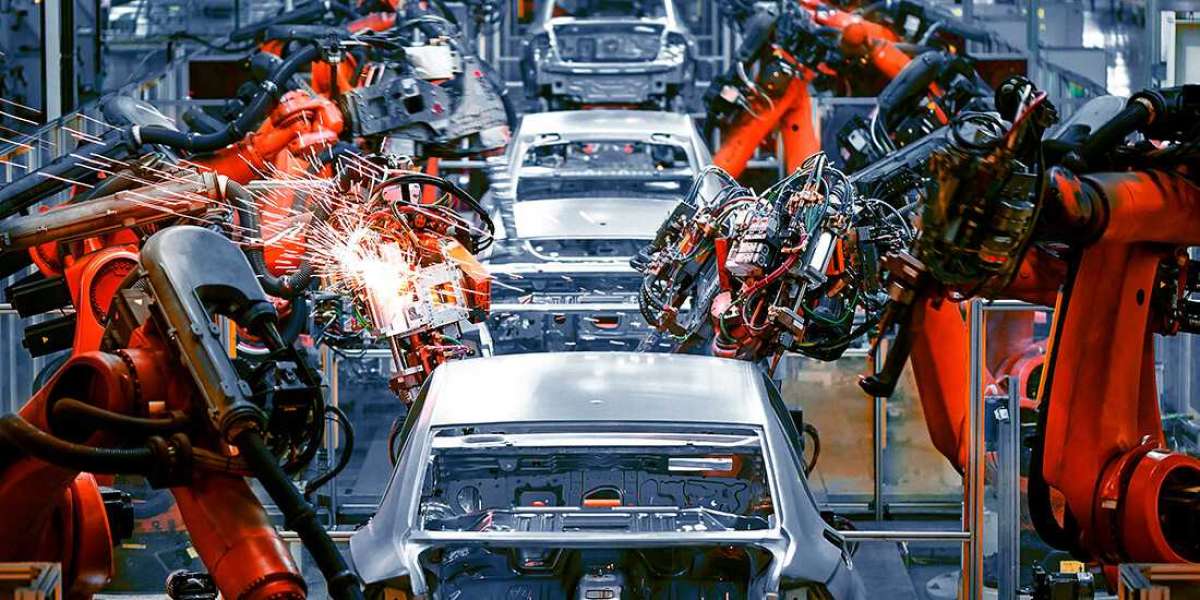

Their automated functionality permits them to function across the clock and on weekends—as well as with hazardous supplies and in challenging environments—freeing personnel to carry out different duties. Robotic technology also increases productivity and profitability while eliminating labor-intensive activities which may cause bodily pressure or potential damage to workers. For examples of how this may look in in style robotic languages see industrial robotic programming. Motion management – for some purposes, such as easy pick-and-place meeting, the robotic want merely return repeatably to a restricted variety of pre-taught positions. For extra subtle purposes, such as welding and finishing , movement must be constantly managed to follow a path in house, with managed orientation and velocity.

Find out how Cost-effective, protected, and versatile collaborative robots - or cobots - are making automation easier than ever for companies of each size. Blog Read about how collaborative robots are decreasing the automation barrier Case stories Discover the stories behind our customer's success. Events Webinars Register to attend certainly one of our workshops, seminars, or webinars. E-book Library E-books that will help you get began and succeed with collaborative robot automation. 2010 brought an enormous acceleration in demand because of the continued innovative growth and improvement of commercial robots.

In both production and dealing with functions, a robot utilizes an end effector or finish of arm tooling attachment to hold and manipulate both the tool performing the method, or the piece upon which a course of is being carried out. Positioning by Cartesian coordinates could additionally be accomplished by entering the coordinates into the system or by using a train pendant which strikes the robotic in X-Y-Z instructions. It is way simpler for a human operator to visualise motions up/down, left/right, and so forth. than to maneuver each joint one at a time. When the specified place is reached it's then outlined in some way explicit to the robotic software program in use, e.g.

End effectors are incessantly extremely advanced, made to match the dealt with product and usually capable of selecting up an array of merchandise at one time. They might make the most of varied sensors to aid the robotic system in locating, handling, and positioning merchandise. Robot simulation tools permit for robotics programs to be conveniently written and debugged off-line with the final model of the program examined on an actual robot. The capacity to preview the behavior of a robotic system in a virtual world permits for a selection of mechanisms, units, configurations and controllers to be tried and examined before being applied to a "real world" system.

FANUC robots are simple to function and provide full flexibility thanks to a variety of application-specific choices, straightforward integration, payloads up to 2,300kg and most reaches up to four.7m. Because they can be programmed to perform dangerous, dirty and/or repetitive tasks with consistent precision and accuracy, industrial robots are increasingly used in a big selection of industries and functions. They are obtainable in a extensive range of models with the attain distance, payload capacity and the number of axes of travel of their jointed arm being the commonest distinguishing characteristics. Modern industrial robotic arms continued to evolve within the 1960's and 70's across the globe. The competition from corporations around the globe continued to produce a excessive demand for industrial robots.

Robotic portray is used in automotive manufacturing and lots of other industries as it will increase the standard and consistency of the product. Despite the rising demand for grippers and EOATs, little analysis is out there on this important market segment. To gain more perception into this evolving market, we analyzed trends within industrial robotics to discover out how they might have an result on demand for end effectors. We also examined buyer preferences to identify the components behind buy choices for grippers and EOATs.

That determine represents about 45 percent of the whole market progress expected over those years, and it’s greater than the combined contribution of Europe and North America. Of the $5.1 billion in market worth for grippers and EOATs in 2023, greater than $1 billion will come from China. Many of the most oppressive and routine office chores—those which would possibly be soiled, dull, or dangerous—are now completely throughout the robotic realm.

Technology developments in sensors and grippers hold promise for expanding the range of actions that the robotic end-effector can carry out. Programming interfaces will proceed to become extra intuitive, not just for cobots, but additionally for traditional industrial robots. The use of commercial robots and automation has seen exponential progress in the manufacturing sector over latest years. In the previous, robots have been asked to do very particular tasks, often in a set location.

Mobile robots and drones monitor oil and gasoline pipelines and electrical transmission systems performing common inspection and looking for indicators of maintenance needs, to efficiently dispatch upkeep groups. Robotic picking and packaging will increase speed and accuracy together with reducing production prices. Robotic automation for machine tending is the method of loading and unloading raw supplies into machinery for processing and overseeing the machine whereas it does a job. Material dealing with robots are utilized to move, pack and select products.

Equipped with quite a few sensors, navigation methods and cameras, the robotic navigates store aisles alongside employees and clients to scan flooring for hazardous conditions like spills. Concurrently, the robot keeps stock on lacking, mispriced or misplaced inventory. But in the future, autonomous robots will work in all elements of retail, from the warehouse to delivery. The programmability of commercial robots was largely a software that could permit them to be used for a wide selection of completely different tasks, but it did not actually give them intelligence. They completed monotonous and unsafe duties and have been deployed for his or her precision and repeatability. As a end result, the automotive trade has been an important customer of industrial robots since 2010, based on the International Federation of Robotics.

At the peak of the robot boom in 1984, Unimation was acquired by Westinghouse Electric Corporation for 107 million U.S. dollars. Westinghouse bought Unimation to Stäubli Faverges SCA of France in 1988, which remains to be making articulated robots for general industrial and cleanroom functions and even purchased the robotic division of Bosch in late 2004. Industrial robotics took off fairly shortly in Europe, with both ABB Robotics and KUKA Robotics bringing robots to the market in 1973. ABB Robotics launched IRB 6, among the world's first commercially obtainable all electrical micro-processor managed robotic. The first two IRB 6 robots were sold to Magnusson in Sweden for grinding and sharpening pipe bends and were put in in manufacturing in January 1974.

These tasks have been executed reliably, robustly, and with high precision. Among them, particular consideration could be drawn to a know-how improvement consisting of a graphical consumer interface that facilitates robotic plasma utility over arbitrary, curved surfaces. Our TS2 SCARA robotic range with its proprietary JCS drive know-how facilitates ultra-short cycle occasions and high repeatability. Its revolutionary encapsulated design opens up new possibilities for use in delicate environments.

An industrial robot, FS-06, made by Kawasaki Heavy Industries, Ltd., was used as a slave arm in this experiment, six-axis force/torque sensor is put in on the wrist of the slave-arm. AI methods are conceptual analytical instruments versus application-specific methods. The fundamental options of business robots are described with sure parameters which are forming their technological capabilities. In the desk 1 are given the importance or how essential is to contemplate these features on the case of space of utilizing the industrial robot.